Titanium has an impressive record of success in racing and high performance vehicles, and its future in the automotive industry is promising.

According to a report on Lucentile, the total market size for titanium in the automobile industry will reach approximately $0.25 billion by 2027. The growing demand for titanium in the automotive industry results from emerging market trends.

This includes increased consumer demand for fuel-efficient and eco-friendly vehicles. Interest in reducing vehicle weight and improving performance has also surged among automobile manufacturers.

Compared to other metals, titanium has high strength, low density, and excellent resistance to oxidation and corrosion.

These properties make titanium ideal for manufacturing lightweight vehicles. It’s worth noting the applications of titanium in vehicle design are broad, and this has led to the creation of OEM partnerships between titanium suppliers and automakers. Read on to understand the applications of titanium in innovative car design.

Supports Weight Reduction in Cars

Today’s commuters are more conscious about their environmental impact. For this reason, more vehicle manufacturers are embracing innovative designs and lightweight materials.

By incorporating lightweight materials in car design, automobile makers can easily achieve their goal of reducing fuel consumption, thus promoting green mobility.

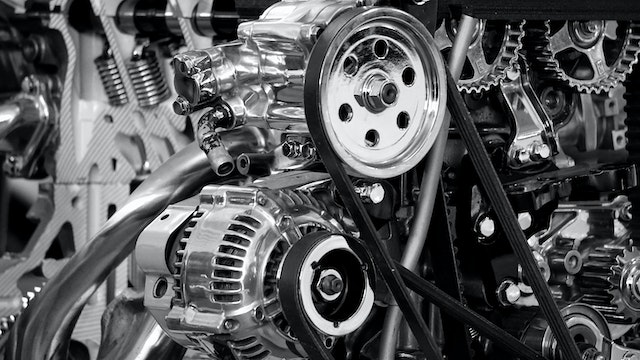

With that said, automobile manufacturers are turning to titanium to build strong but light vehicles. While automakers have been using titanium to build valve springs, connecting rods, exhaust systems, valves, and retainers, today titanium is a preferred material for building car frames, hood covers, doors, and other body panels.

Car manufacturers in the electric vehicle sector also use titanium to create underbody panels. Because titanium can withstand extreme temperatures, it prevents battery fires in electric vehicles.

Extends the Lifespan of Car Parts

Durability and strength are key reasons car manufacturers use titanium to make vehicles. This metal is also resistant to weather damage, meaning it’s non-corrosive.

These unique properties explain why the demand for titanium metal supply is high in the automobile industry.

Automakers need an unlimited supply of titanium to design long-lasting car components. For example, springs made of titanium resist corrosion, they are durable and stronger than those made from stainless steel.

Car makers also use titanium to improve the service life of turbochargers. Because of its high melting point, titanium is a desirable metal for designing turbochargers whose primary function is to boost the engine’s power output.

Provides Strength When Fusing Glass and Metal

The ability to fuse metal and glass together is one of the most impressive innovations in this digital age.

This innovation allows automakers to integrate glass and metal seamlessly to achieve smooth lines and improved aerodynamics.

Because of titanium’s strength and rigidity, automakers can use it in this design concept to speed up the production of light and high performance cars.

Although car manufacturers use laser technology to weld glass and metal to prevent stress, using titanium plates or sheets helps maintain product quality.

The flexible nature of titanium ensures car parts aren’t compromised by many stress points during welding.

For decades, automakers have been harnessing the strength and corrosion resistance aspects of titanium to design springs, valves, gearbox housing, and connection rods.

Today, titanium is a perfect choice for innovative car designs, such as manufacturing lightweight vehicles.

Car makers also use titanium to build durable components, complex or customized designs, and enhance strength and quality when fusing metal and glass.